As mentioned in my blog about hidden costs in digital printing, printing speed is a factor that greatly influences the cost of digital textile printing. The maximum speed of a printer is often being used as a Unique Selling Point (USP) by printer manufacturers. However, in the long run, it is not the printing speed that is most important; the final printing quality that can be produced is the priority and that determines the printing speed that can be achieved.

A printer with astonishing printing speed might sound amazing as a sales argument, especially for the buyer who doesn’t know better. After all, printing faster means more printed textile, which equals more revenue and lower cost per linear meter. Sadly, this promised maximum speed is seldom achievable in combination with the required printing quality.

Top speed: asking the right questions

When a certain maximum speed is specified for a printer, it might sound like this printer is the real deal. Time is money, and faster printing means that you will save a lot of time, right? However, there are some questions you need to ask yourself before drawing this conclusion.

First, the industry you are working in determines greatly what kind of printer you will need. It is also important to focus on the results: what do I need to produce? Furthermore, it is inevitable to look at the reliability and endurance of the printer. How long is the printer going to last while printing at maximum speed? It is much more important to know the number of sellable meters the printer is going to bring you each day, week, month, or year.

In short, there are three main questions concerning speed you need to ask when considering a printing investment:

- What quality does the printer deliver at the maximum speed?

- Can you sell all those meters that a printer running on maximum speed can produce in a month or year?

- Will the printer last long enough when it is always running on its maximum?

Your need for speed: do you really need a high speed digital textile printing machine?

A guaranteed maximum speed instinctively seems like a justifiable investment, but for a lot of printers, the maximum speed is only reachable on certain fabrics or surfaces. Therefore, you should ask yourself an important question before investing in a fast printer: what is a realistic speed for the fabrics I am working with? Do I really need a printer with a higher maximum speed?

The bedding industry, which uses more pastel colours and large areas of white, can probably print fabrics with higher speed than the fashion industry, where more detailed prints with more coverage are often requested. So a fast printer that you can never use with that maximum speed because the ink lay down is too low, will cost you unnecessarily. Always take the bigger picture into account: what does the printer deliver in the long run? Faster is not always better.

The costs of speed: high speed digital textile printing machine

One of the reasons why fast printing often results in less printing quality is the amount of ink the printer can drop per square meter given a certain speed between the printheads and the fabric. The faster the fabric passes under the heads, the less ink is sprayed onto an area. This is the case in both scanning as well as single-pass printers. Compare it with moving your hand under a running tap of water. The slower your movement, the wetter your hand will become.

How much ink can the printer lay down at a certain speed level? Focus on the achievable result, not on the printing speed. What impact does printing speed have on the result? You don’t need the fastest Ferrari if all you do is drive downtown to your office.

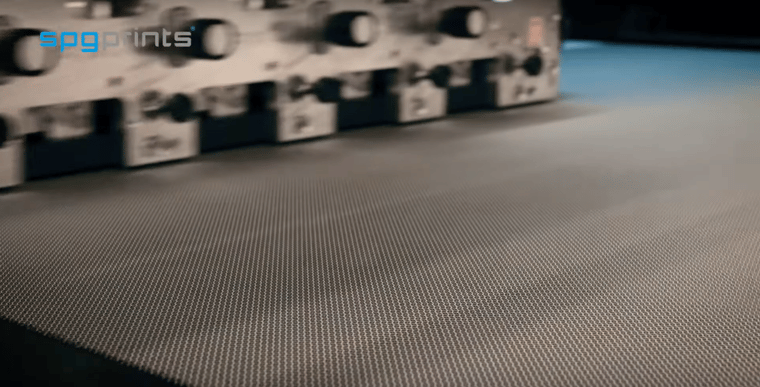

That’s why we limited our PIKE to 60 meters per minute. At that speed, the PIKE can still lay down the same amount of ink per meter as any scanning printer on the market today, even at the highest quality mode. Single-pass printers that advertise higher speeds will be able to run those speeds, but cannot lay down enough ink to print high coverage and high color density designs. Besides that please realize the following: a single pass printer can run almost continuously as it does not need to stop to change designs. Running 60 meters per minute, 20 hours a day and 250 days a year gives 18 million meters of printed fabric per year. Can you sell 18 million meters of digitally printed fabrics per year?

Width of the canvas: impact on your high speed digital textile printing machine

Buying a printer for its promised maximum speed is a bad bargain if you hardly ever are able to use this maximum speed in your production process. Most vendors express printing speed in the number of meters per hour. However, to determine if you could reach this printing speed in your production process, you must take the width of your fabric into account. Most vendors make their calculations based on a canvas width of 1.50 meters. However, in the fashion industry, a fabric width of 1.80 meters is quite common. That means that most printing companies delivering to fashion brands would never be able to reach maximum linear speed. For that reason, an important question you should be asking is: what are the speed levels of the so-called "high speed digital textile printing machine" for the fabric width you’re using?

Even if printer manufacturers quote the speed in square meters per hour, you have to be careful. If the printing blanket is 1.85m and your fabric width is 1,50m, make sure the carriage in a scanning machine does only cover the 1,50m with each stroke, otherwise you still have a lot of unproductive time for the carriage to move over the whole width. And even then, if the fabric is mounted in the middle but the carriage has to go regularly to the home position to clean the heads (see my blog about ‘hidden costs’) it means extra unproductive minutes to cover the width of the blanket where no fabric is mounted.

For the best return on investment, you have to wonder: can I use the printer most of the time at its top speed? Not all industries profit from a faster printer. Can your printer reach its maximum speed in the production process you are working with? If the answer is no, investing in a very fast printer is unnecessary overkill.

High speed digital textile printing machine versus high quality

In conclusion, great speeds are promised by printer manufacturers, but common sense must prevail at all times. Always focus on the printing process as a whole. Do you actually need a printer at maximum speed? Does maximum speed deliver you the required quality for your products?

In order to make an accurate comparison when it comes to this so-called “maximum speed”, you should compare the quality of samples and the speed level these samples were produced on. What level of quality can be produced at what speed level? The golden rule is that the highest speed will never deliver the highest quality.

Turkish manufacturer Tekboy Tekstil searched for a way to enable high-quality printing at a higher speed and made this wish come true with the help of digital printing. Curious about how they did this? Read our case study for the entire story: