1. Speed to market

In rotary screen printing, the printing process is slowed down by various processes. First of all, the printing design has to be adjusted with special separation software so it only consists of limited amount of colors (color separations). After that is done, for each color used in the design a special screen has to engraved. The engraving process means extra costs and takes time. When the screens are finished, they have to be installed in the printing machine and registered so all colors match up perfectly. For these reasons, the route from digital design to printed fabric can take up three to six weeks.

In digital textile printing, the printing process is much shorter. The digital design first has to be ripped (raster image processing) — which takes up a few minutes, (depending on the size of the file) — after which the design can be printed directly onto the fabric. In an hour time, you can already have printed hundreds of meters of fabric.

This enables printers to accelerate their speed to market and meet increased customer demands for faster deliveries. A delivery time of weeks or even months can, with help of digital textile printing, be brought back to days.

2. Design flexibility

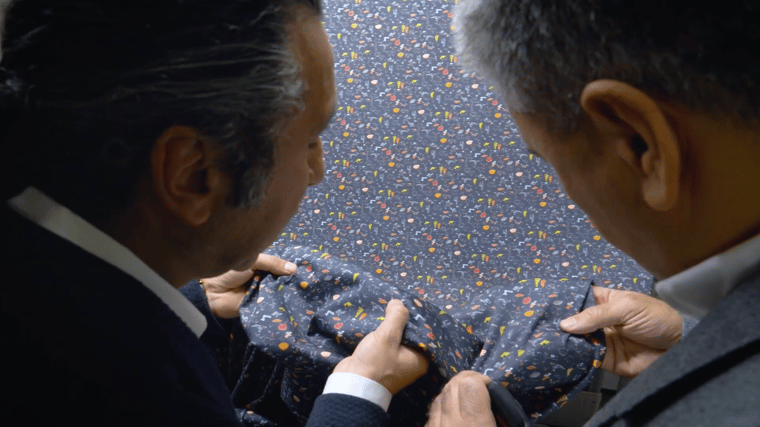

As pointed out before, in rotary screen printing designs have to be brought back to a limited amount of colors (typically 6 or 8 colors, maximum 24 colors). On top of that, the design that is engraved in the screen repeats itself every full rotation of the screen (typically every 64 centimeters). Both these characteristics of rotary screen printing seriously limit the flexibility in designs that can be used.

Both design limitations do not apply to digital textile printing. This means designers have more freedom in their design and can experiment with new color combinations and extend their designs. Although most fabric designers are used to design with these limitations in mind, the new, younger group of designers entering the market are willing to experiment and create designs that astonish customers.

3. New business models

The accelerated speed to market that digital textile printing enables opens up new business models for printers who are ready to make the transition. Instead of selling what has already been printed, digital textile printing enables fashion brands to print small batches and place repeat order when a certain type of clothing is selling really well. Ideally, this means that in the future fashion brands don’t need to sell surplus stock with a great discount anymore.

Digital textile printing: the costs versus the earnings

Do you feel like a digital textile printer could be of value for your company? Then first you want to find out exactly how this transition could help you grow your business and get ahead of the competition.

Knowing which core advantages of digital fabric printing helped other textile printers to address new business units and assure a profitable future for their company will help you to make that decision. In our latest guide, we discuss 4 different digital textile printing journeys and how to find a digital textile printer that best suits your needs and those of your customers. Curious to discover your digital textile printing options? Download our newest whitepaper directly: