The direct cost comparison

The numbers of colors in use

When making a cost comparison between rotary screen and digital printing, the number of colors in use in rotary have to be taken into account. For each extra color you want to use in rotary, a new screen has to be engraved. Needless to say, the more colors that are used in a particular design, the higher the initial costs.

Of course, these costs are then also dependent on the meters of fabric you are going to print of a particular design. The more meters you print with a particular set of screens, the lower the costs of screens per printed meter. On top of that, you need to take into account the number of colorways that you want to print from the same design. If you print more colorways with the same set of screens, the costs are divided over more printed meters.

In digital printing, however, the print heads are able to produce any possible color without additional adjustments. This means that when printing a design that consists of more colors no additional costs are made. Changing colors to make another colorway can happen instantly and unlimited number of times, where in rotary printing you need to clean out the printing paste in each screen and replace it for the new color paste. For that reason, digital textile printing can be a more cost-friendly option for printing companies that work with very colorful designs and many color ways per design.

Speed

Another positive driver in favour of digital textile printing is the acceleration of the printing process. Since no screens have to be engraved, lead times can be shortened considerably. A digital file of a design can be loaded into the digital printing machine in a matter of minutes after which it can directly be printed on fabric. This enables printers to keep up with fast-fashion demands for shorter lead times and acceleration of the time-to-market.

In rotary screen printing, on the contrary, a design has to be adjusted with special separation software to reduce the number of colors. This is limited to the number of screen positions that the rotary printer has. Although there exist 24-color rotary machines, most customers are limited to 12 colors but often reduce to 6 to 8 colors to save costs of screens. After that separation process a separate screen has to be created for each color. When the screens are engraved, they have to be installed and registered in the rotary printing machine so all colors match up perfectly. Beside the fact that this creates waste fabric as long as the registration between colors is not set, all these additional steps in the rotary screen printing cycle — from design until finalized product — take three to six weeks.

The batch length

Another valuable parameter in a cost comparison is the batch length that you expect to print with the specific technology. The obvious question is the break-even calculation of both technologies: until what print length the costs of digital are lower than rotary?

This break-even point depends on different parameters, mainly in the rotary printing process. As pointed out before, it heavily depends on the number of colors you want to print, the number of color ways and the number of printed meters per color way. But also in which country you are going to print, for example. As rotary printing requires a lot more labour than digital, the labour costs from country to country can significantly influence the cost per meter in rotary.

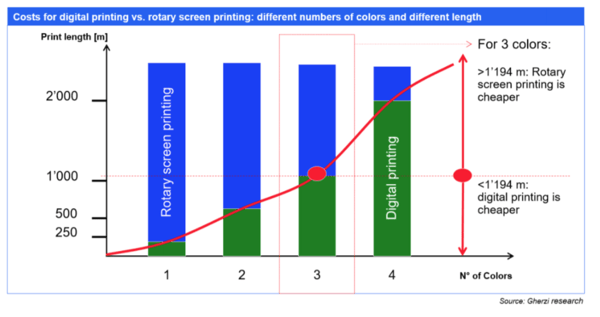

In an independent study conducted by Gherzi (www.gherzi.com) an estimate was made about the break-even point between rotary and digital. This estimate is a rough estimate: the exact break-even point is dependent on each specific printing company and for instance also depending on the country you are printing in. Gherzi estimated that in general when printing less than 1200 meters of a certain design digital textile printing is cheaper than rotary screen printing. Do you print more than 3000 meters of a certain design? Then, according to Gherzi, rotary screen printing is a more economical choice. In case you print between the 1000 and 3000 meters of a single design then it heavily depends on your specific situation (see Figure 1, source: Gherzi whitepaper, 2017).

The evaluation of indirect costs

The number of colors and the print length are the main direct costs parameters which are essential in a cost comparison of digital and rotary screen printing. However, there are various indirect costs that — in order to get a realistic idea of the total price tag of a printing technology — have to be taken into account. Although, it is difficult to quantify these indirect costs in monetary values, they do have a great influence on the way digital textile printing can help you either save costs or attract new business.

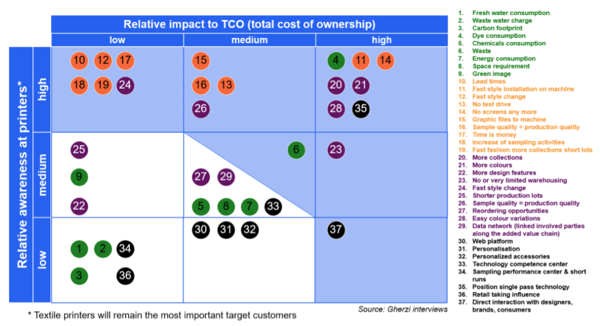

Find a full overview of all indirect cost drivers for digital textile printing in Figure 2, as listed in a recent study by Gherzi. Below, I’ll specify the most important indirect costs in more detail.

Figure 2: Digital textile printing indirect cost drivers

Sustainability

Sustainability is increasingly becoming a more important issue among textile printers. Digital textile printing can effectively help printers to reduce their carbon footprint and improve their green image. With its low dye consumption and reduced waste material (95% less waste), printers can effectively save costs while contributing to the environment. On top of that, digital textile printing helps printers to reduce water consumption by 60%, chemical usage and power consumption by 55%.

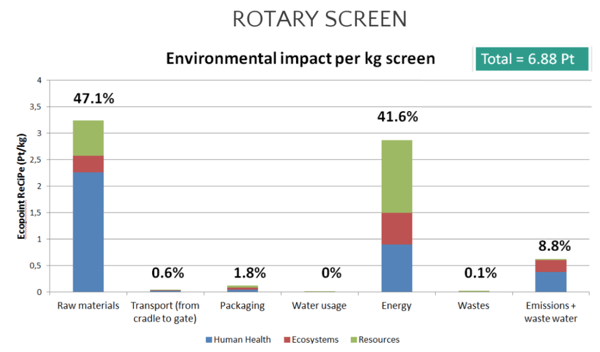

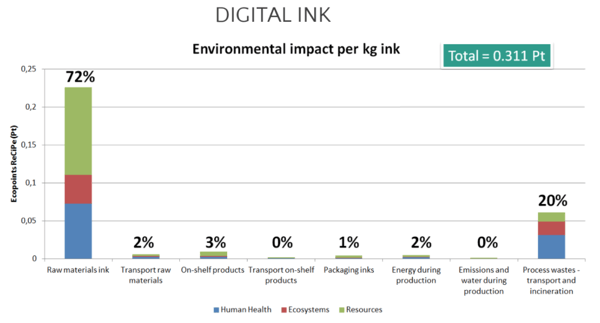

Below, you’ll find both the environmental impact of rotary screen printing (Figure 3) as well as digital textile printing reviewed from cradle to gate, so the production phase of the consumable (Figure 4, source: internal study SPGPrints, 2015).

New business models

Digital textile printing provides printers with the ability to benefit from new business models. The most important one is printing what you’ve already sold instead trying to sell what you already printed. Because of the flexibility of digital textile printing, fashion brands can decide to have small batches of a certain design printed and place repeat orders when that product is selling well. Ideally, this means that in the future discount sales are no longer necessary.

On top of that, the fashion industry is changing as a result of digitalization. Nowadays, people like to buy their clothing online and are used to having a lot of different options to choose from. Fashion brands are under the pressure to produce a large variety of designs and rapidly respond to changes in trends. Digital textile printing helps printers to directly print a new order and have it delivered to the customer in a short time frame. This way, fashion brands are able to meet their customer’s demands and will therefore be more willingly to collaborate with digital printing companies instead of conventional ones.

Learn more about the difference between digital textile printing and rotary screen printing when it comes to fast-fashion manufacturing in the video below:

The three core investment reasons of digital textile printing

Did your cost comparison show that digital textile printing could be of value for your printing company? Then it’s time to discover precisely how this transition can make your business grow.

In an independent study, Gherzi identified the three main investment reasons for digital textile printing. Three core advantages of digital textile printing that have helped other textile printers to address new business units and assure their businesses of a future.

Find out what they are and if they could be of value to your company by downloading the Gherzi white paper: