Although digital textile printing has helped to increase quality levels, accelerate time-to-market and create completely new business models, there is one important challenge almost all digital printing companies face: maintaining a high and above all stable printing quality. Are you interested in improving your quality levels significantly thanks to a new digital textile printing technology?

Delivering quality levels at a faster rate

Digital textile printing technology has enabled many printing companies worldwide to keep up with the ever-changing requirements of the textile market. Major trends like population growth, increasing purchasing capability and rapidly changing fashion trends are key drivers for growth in the textile printing market. The low sampling costs, fast time-to-market and high resolution of digital textile printing technology have enabled the textile printing industry to give an adequate response to the demands coming from the fashion industry.

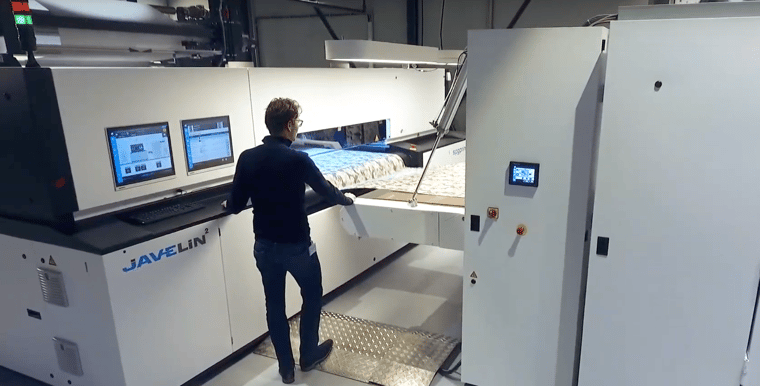

SPGPrints’ digital textile printing technology JAVELIN® has proven to the market to be the solution for these challenges. The Javelin has established a reputation to be able to print the highest quality designs, not seldom designs that other digital textile printers cannot print reliably at all.

Reliable printing with a constant quality level has become one of the most important challenges within the printing process, and one that regularly frustrates digital textile printing companies. An important disadvantage of digital textile printing technology is that it is intrinsically more sensible for print head errors. When one of the nozzles gets clogged, no ink can be printed on the substrate by that nozzle which often will create a visible white line in your design. Nozzles that are not jet straight will lead to mispositioned drops that are often visible and disturb the image quality of the design.

Of course, these specific nozzle errors stand in the way of delivering stable quality levels at a fast rate. On top of that, clogged or damaged nozzles have a negative influence on the life span of the print heads. As print heads require quite the investment, digital printing companies will welcome any way of extending their printers' life span.

What is Archer+?

Luckily, the brand new Archer+ technology helps digital textile printing companies to conquer these challenges within their printing process. Archer+ is the extension of the Archer® technology, which is currently used on all Javelins. The Archer® digital textile printing technology is an innovative printing system that helps printers to increase quality through its smaller drop-size range and higher resolution (true 1200 dpi).

Archer+ provides users with all the advantages of the Archer technology and many more. Archer+ is the solution for automatic and operator-independent adjustments of the individual nozzles of your digital textile printer. Therefore, using the Archer+ technology ensures perfect uniformity in blotches and undisturbed geometric patterns. Besides that, it enables users to choose a higher speed setting to print a certain design, which leads to a higher printing capacity of each Javelin per month or year. It even enables single-pass printing modes on a scanning printer!

Until recently, there was no affordable technology available that was capable of processing such large and complex calculations. To illustrate its complexity: the Javelin is equipped with almost 70.000 nozzles. Analyzing and adjusting the jetting behavior of all these nozzles on the fly requires a significant amount of computing power.

How does this digital textile printing technology work?

The Archer+ calibration process uses a dedicated Archer+ scanner to scan some printed test files. This process takes less than half an hour of operator time. The scanning results are then analyzed automatically by the Javelin image processing software and translated to individual nozzle compensation routines. The total process for Archer+ calibration takes less than 2 hours lead time and is recommended to be implemented in a weekly maintenance routine.

Important characteristics of the new Archer+ technology:

- Automatic calibration on a regular time basis (depending on the utilization of the printer this is once every few weeks up to once a week)

- Operator-independent process

- Variations between individual printheads of the same colors are completely eliminated, which also ensures seamless integration of replaced printheads in any print bar

- Automatic adjustments to all individual nozzles within one printhead

- Possibility to upgrade existing JAVELIN digital printing lines.

The advantages of Archer+ for your printing performance

The Archer+ digital textile printing technology was created especially for companies to further reduce their challenges and optimize their digital textile printing process. For that reason, the technology is a valuable asset for all Javelin owners and future investors in digital textile printing equipment. Curious how the Archer+ technology could help you optimize your printing performance? Below, you’ll find the most important advantages of this technology:

- Maintaining optimal and stable print quality over time

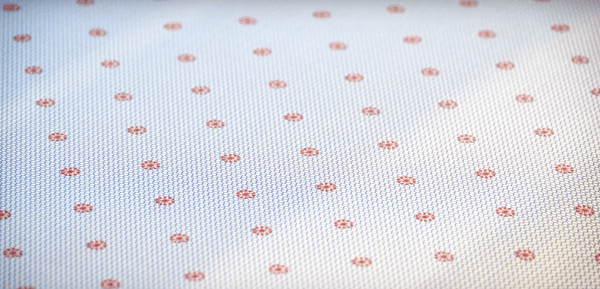

When using a digital textile printer, providing your customers with a stable printing quality is a must. However, common nozzle errors like clogging or jet angle deviations have proven to be an important risk in reaching this goal. With the Archer+ technology, the required adjustments are made to each individual nozzle automatically and completely operator-independent. This way, nozzle errors don’t have to stand in your way anymore in reaching and maintaining an optimal and stable print quality over time. - Finer definitions and more uniformity

The Javelin already provided its users with superior printing quality. With the help of Archer+ technology, this quality level has been increased even more. With this new digital textile printing technology, your digital textile printer can produce finer definitions and print designs that previously were not possible to print. - Increase the pace at which your designs can be printed

The Archer+ digital textile printing technology enables you to also accelerate the speed at which you print your designs because you can choose faster print modes without compromising quality. Due to this acceleration, you basically have two machines in one. - Extend the life span of your print heads

Due to the automated analysis and calibration of the nozzles, the Archer+ enables you to detect and solve print head errors more easily than before. Therefore, the Archer+ technology will allow you to print longer with your existing print heads and lower the total cost of ownership.

Experience the unlimited possibilities of the Archer+ technology

Do you want to witness the advantages of this technology in real life? Witness the true power of the Archer+ technology yourself by scheduling a visit to our digital textile printing Experience Center.

In our Experience Center, you get the opportunity to:

- See the PIKE and JAVELIN digital textile printers in action

- See the process and results of Archer+ technology while printing your own designs on your own fabrics

- Witness our digital printer's high-quality output at first hand

If you want to read more about the Archer+ technology and its advantages first, download our free Whitepaper with all ins and outs here: