How can you benefit from digital textile printing to enable fast-fashion manufacturing and provide new standards of production efficiency?

What is fast-fashion manufacturing?

Back in the day, brands hired trend watchers to predict what people would want to buy next season. Based on their conclusions, the new collection was designed. Out of hundreds of designs, they had to select which ones have to go into production and with what quantities. Although this tactic can be very successful, there was always a large margin of error. To still be able to sell the clothes that weren’t as popular, brands gave their customers a discount on the clothing, also known as the sale.

Nowadays, large fashion brands have adopted a smarter, more innovative method to reduce the number of clothes they’re left with at the end of the season. Since customers expect fashion collections to change more often, more and more brands decide to adopt this new production method to make sure they keep up with the emergence of fast-fashion manufacturing.

This new method stimulates brands to speed up their distribution model significantly. To keep up with the fast-fashion manufacturing trend, brands don’t have to decide which design to produce. They simply produce smaller amounts of each design and rapidly produce more of it when a certain piece of clothing is selling very well. That way, brands can more easily respond to the market’s needs and make sure they are not left with large amounts of unsellable clothing at the end of the season.

Fast-fashion manufacturing

The fast-fashion trend, however, does not only require a new distribution model from fashion brands. It also requires the textile printing industry to speed up its production process. Fast-fashion manufacturing, therefore, requires a very fast printing technique.

When brands notice that a certain piece of clothing is selling well and they rapidly want to restock, they need a printing partner who can deliver them the printed fabric in a very short time frame. What printing technique enables textile printers to keep up with this new distribution model and start with fast-fashion manufacturing?

Fast-fashion manufacturing: conventional versus digital textile printing

Which printing technique best facilitates fast-fashion manufacturing: conventional or digital textile printing? To make a comparison, first, we need to know exactly what printing specifications fast-fashion manufacturing requires.

First of all, fast-fashion manufacturing requires fast delivery times for both first as well as repeat orders in order for brands to quickly restock best-selling clothes. Because of this new distribution model, fashion collections change more often. So the unlimited design possibilities, the possibility to start printing almost instantly, and the low setup costs of digital textile printing clearly enable fast-fashion manufacturing.

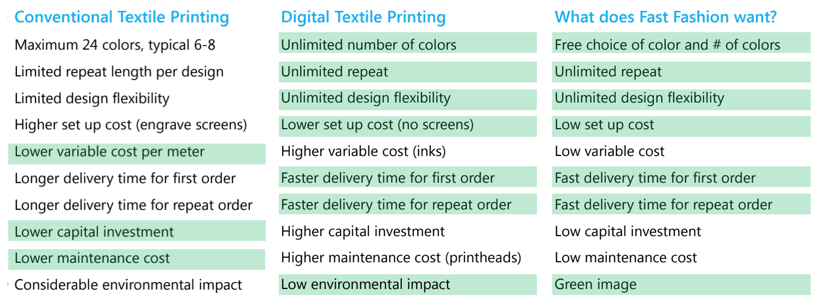

On top of that, the modern customer demands new, high-quality designs that rapidly follow the fashion trends and prefer brands with a green image. In figure 1, you can see an overview of all the requirements of fast-fashion and in which way both conventional, as well as digital textile printing, matches those requirements.

Fig 1. Fast-fashion manufacturing: conventional versus digital textile printing

As becomes clear from figure 1, digital textile printing best matches the requirements of fast-fashion manufacturing. That also becomes clear in practice: fast-fashion brands are the largest purchasers of digitally printed textiles.

However, an important disadvantage of digital textile printing in comparison with conventional textile printing are the higher variable cost, maintenance cost and last but not least the higher initial investment. In the next paragraph, I explain how you can reduce the costs of digital textile printing in order for it to match all fast-fashion manufacturing requirements.

Reducing the cost of digital textile printing for fast-fashion manufacturing

The cost of digital textile printing compared to conventional printing methods depend on a few factors:

- The length of the run

Long runs are cheaper in conventional printing: high initial costs are distributed over a large number of meters while the variable costs are lower. Short runs, however, are cheaper in digital printing: higher variable costs per meter are compensated by the lack of initial costs.

- The number of colors

In digital textile printing, a digital design is printed directly on fabric. No rotary screens are needed. This does not only saves printers valuable engraving time, but printers also spare the additional costs of the screens themselves plus the engraving of the screens.

- The number of color ways

The costs are also dependent on the meters of fabric you are going to print of a particular design. The more meters you print with a particular set of screens, the lower the costs of screens per printed meter. On top of that, you need to take the number of colorways into account. If you print more colorways with the same set of screens, the costs are divided over more printed meters.

- The number of repeat orders

When there’s a large number of repeat orders, the costs of engraving screens for a particular design decrease since the same screen can be used multiple times. That means you can print more meters with the same screens.

- The number of designs

Finally, the number of designs that you need to print influences the overall costs of the printing technique. Since in screen printing a new set of screens has to be produced for each design, the cost of this conventional printing method will increase when a lot of different designs have to be printed.

If you’ve made a cost comparison and digital textile printing turns out to be the most sufficient technique for your fast-fashion manufacturing, there are a few things you can do to reduce the cost of this printing technique:

- Capital investment

Digital textile printing has a high capital investment. This means you have to select a digital printer that has a high reliability in order to increase efficiency and simultaneously reduce downtime. That means that in the end, you can produce more in a shorter amount of time and increase your revenue.

- Maintenance costs

The maintenance costs of digital textile printing are largely made up of print head costs. So when you select a digital textile printer, you should carefully study the lifetime and warranty conditions that are given by the printer manufacturer for the printheads that are used in that printer. Furthermore, a digital textile printer that gives you easy access to the print heads enables you to quickly exchange and adjust print heads that are broken. That not only saves you time but also decreases the maintenance costs of digital textile printing.

- Variable costs

The largest contribution to the variable cost of digital printing comes from the inks. So obviously, by reducing the ink consumption per meter you can reduce the variable costs of digital textile printing. You can do that by using high-density inks so you need less ink per meter to reach the desired print quality. On top of that, using a digital textile printer that needs less cleaning and purging, will produce less waste ink. Furthermore, a good printer results in fewer rejections which helps you to increase overall costs even further.

SPGPrints proprietary Archer Technology addresses all of the above aspects to improve the cost situation for digital textile printing. Watch my presentation about fast-fashion printing at the WTIN Textile 4.0 Conference below:

Learn how other textile printers keep up with fast-fashion manufacturing

With the growth of fast-fashion, manufacturing of textile faces challenges in keeping up with customers demands. Dong Heng was one of the companies encountering these challenges, as the Chinese textile manufacturer wanted to increase production capacity while meeting fast-fashion delivery times. Read their success story here.

Another one was Adalberto Estampados. wanting to address the growth of fast-fashion and offer new standards of quality. With fashion brand Zara as one of their biggest customers, Adalberto Estampados wondered how they were going to produce more challenging designs, offer new standards of quality and production efficiency. With digital textile printing, they managed to meet their customer’s demands. Learn how you can do the same by reading their case study: