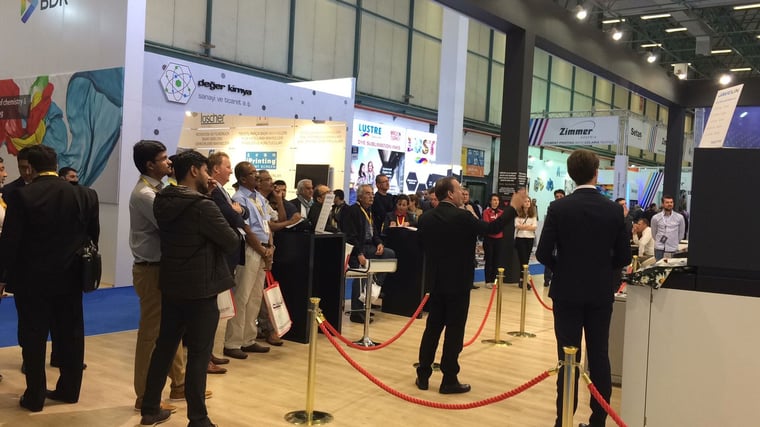

From the 14th until the 17th of April the whole textile world gathered in Istanbul, Turkey for the largest textile exhibition in Turkey: ITM. In these four days, textile printing companies were able to learn all about the latest technologies in textile printing, to find out how printing processes could be optimized and above all how they could reach a new, unheard of level of quality. The most important takeaway message from ITM 2018 - something that we also noticed in our conversations with the visitors - was the growing interest and demand for digital textile printing.

Digital textile printing: meet demands for high-quality designs, short runs, and rapid turnarounds

In conventional printing, which still makes up 95% of the textile industry, the most prominent challenges are the relatively slow turnaround time and not being able to print complex designs - like blotches or geometrics - and fine patterns. From the market, there is an increased demand for exactly these type of textiles. Customers want to print various complex designs in short runs at a faster production rate, while simultaneously being able to guarantee a high-quality output.

Digital textile printing helps printing companies to keep up with their customer’s demands. By enabling fast sampling and short-term delivery, digital textile printing can help your customers to bring new ideas to the market faster. Since the design can be printed on the fabric directly, without the use of screens, printing companies save valuable time and money and can print unique designs rather than designs that repeat itself every turn of the screen.

On top of that, designs can be adjusted digitally on the spot. This gives digital printing companies a competitive advantage over manufacturers using traditional printing techniques. Together with the high image quality that digital printers can produce, digital textile printing provides many benefits for printing companies.

From conventional to digital textile printing

At ITM 2018 we saw more printing companies who were ready to make the transition from conventional to digital textile printing. This transition takes time and above all courage. It requires that printing companies let go of their old techniques - with which they have been working with for decades - and start adopting an entirely new one. However, at ITM 2018 we saw more and more printing companies collecting insights in digital textile printing and preparing themselves for the transition that could help them create a competitive advantage.

A textile printing company which decided to take a leap, optimize their printing process and meet their customer demands is Turkish textile printer Tekboy Tekstil. Their primary challenge was to meet increased demands from their customers for shorter-runs, rapid turnarounds, and on-demand sample production. Making the transition to digital textile printing enabled them to produce high-quality designs at a faster rate and bring new ideas to the market within three to four weeks.

Learn all about Tekboy Tekstil’s transition from conventional to digital printing in the video below. Erhan Kadanali, manager of Tekboy Tekstil, explains what difficulties they faced in the process and how digital textile printing enabled a high-quality production at a faster rate:

How to make the transition to digital textile printing

Are you ready to optimize your printing process and create a competitive advantage over printers using conventional printing methods? And would you like to know how other printers made the transition from conventional to digital textile printing?

In the case study, Tekboy Tekstil shares their success story and explains how they turned their challenges - slow turnaround times, increased customer demands and not being able to print fine patterns and designs - into opportunities. Download the case study here: