Transferring production to digital printing used to demand a significant investment – and a steep and sometimes scary learning curve – but things are changing. Adding digital printing capability can improve your business, helping you to carve out a competitive advantage. The key is to work with a partner that can work with you to select the suitable machine for your operation and market.

Why calculating TCO is crucial

Textile printing is a competitive industry where price matters. Each printing method has its advantages and challenges. Digital textile printing machines, for example, have low fixed costs per design, with customers paying the variable cost of each job. Printing a design with conventional textile printing (rotary or flatbed) has higher fixed costs, but these can be shared across more linear meters that have very low variable costs.

When we look at volumes, it’s clear that conventional textile printing is the cost-effective option for large volumes (5,000 meters+). The sweet spot for digital printing is below 2,000 meters as the fixed costs are low and the variable costs come only from a limited number of meters. Between 2,000 and 5,000 meters the most cost-effective method is determined by design-specific parameters such as the number of colours, the number of colourways or the complexity of the design.

Digital printing is often considered more expensive - when compared to rotary and flatbed machines – but the breakeven point is shifting in favour of digital. Instead of concentrating on upfront costs, it's critical that business owners consider the total cost of ownership (TCO) when deciding whether to go digital.

Businesses exploring whether to shift to digital textile printing are often scared by high upfront investment costs without considering all the other factors that affect the price. When comparing the costs of printing methods, you must include everything – including energy, labour, lead times, consumables and wear-and-tear parts (like printheads in digital). When you’ve processed the numbers, you may discover that the difference between conventional and digital textile printing is much smaller than previously thought.

The lesson: calculating the true TCO is crucial. Only by doing so can you make an informed decision on whether digital printing is a cost-effective option.

Delivering performance to justify premium

Digital textile printing is acknowledged as delivering higher-quality outputs, but are customers willing to pay the premium?

Firstly, as we've outlined above, the price difference is likely to be much less than you may have considered – so run the numbers. New developments are bringing down digital textile printing costs, including the costly print heads that regularly need to be replaced. Digital printers can now use pigment inks that deliver an excellent finished product at a competitive cost because there is no need for steaming and washing.

Businesses that transition 100% to digital may lose extreme price-driven customers, but this is a rare situation. A new range of affordable digital printers enables manufacturers to introduce digital printing capability alongside traditional printing methods. Some customers may be keen to experience the benefits of digital printing; others may need reassurance to develop the confidence to test digital printing technologies.

As a business, you must innovate. Transitioning to digital print is a journey that you – and your customers – need to go on.

Filling the skills gaps

Conventional rotary printers and digital printers use dramatically different technologies and components. Experienced in-house engineers can fix traditional rotary or flatbed printers, but what about digital textile printers?

SPGPrints operates a global network of service providers available to service, maintain, and repair digital printers. We will first attempt to fix your networked digital textile printer remotely. If this fails, an on-site technician will be dispatched to your location. They can be with you rapidly, often within 24 hours.

Our expert support can minimize downtime. As well as servicing and support, SPGPrints can use its unrivalled knowledge to provide you with advice and guidance on how to get the best from your digital printer. So whether you have a question about fabric-pretreatment, file corrections for the best printing result, or finishing, we're always happy to give you consultation based on our 70 years’ experience in textile printing.

Affordable, effective digital textile printing

SPGPrints has been at the forefront of industry innovation for decades. While we are known to deliver top quality at premium prices, we’re now very excited to launch Violet our first affordable digital textile printer. Today businesses of all sizes can afford to run a SPGPrints digital textile printer. Violet is our entry-level digital printer, and it completes our digital textile printing portfolio that includes Rose, Jasmine, Magnolia and PIKE machines. We’re able to support clients from entry-level machines to high-volume, top-quality digital textile printing technologies.

Here are some of the benefits of Violet:

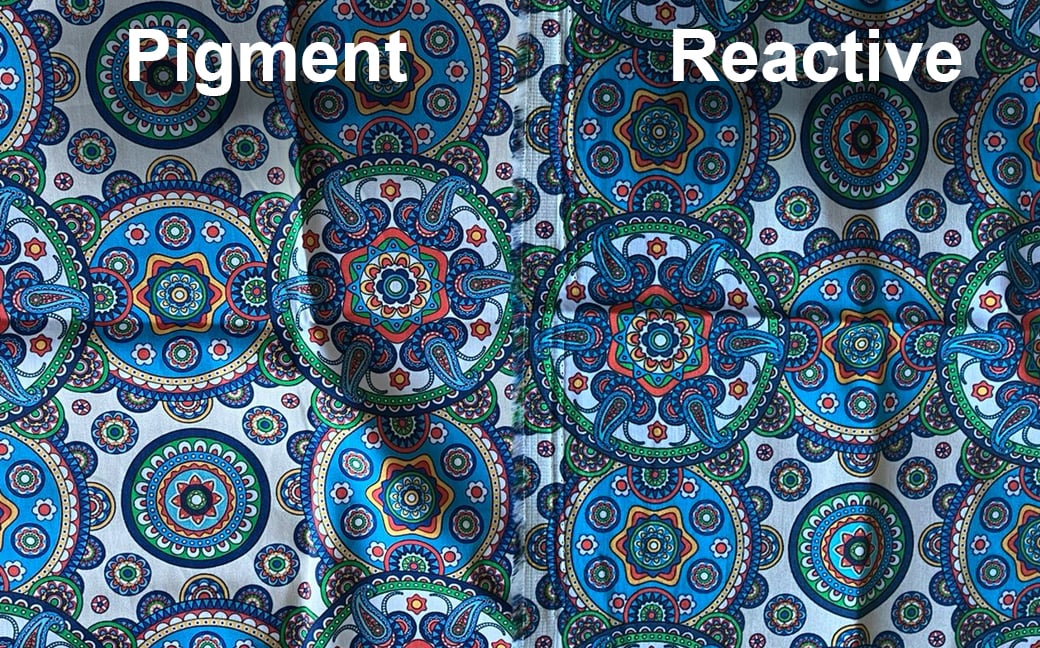

- Compatible with reactive as well as pigment inks, giving you the freedom to choose the best solution for the fabric you want to print

- Complies with the latest legislation and safety certifications

- Exceptional quality textile printing at an affordable price point for all businesses

- Perfect balance between production speed, quality, and overall cost

Breaking down barriers to digital printing

Violet offers every textile printing company the chance to gain experience with digital textile printing services. It’s breaking down barriers for every business, delivering high-quality outputs at an affordable price. Operators can have the confidence that they’ll receive market-leading support from SPGPrints.

Violet delivers industry-leading outputs for a printer at this price point. Once you have gained confidence operating the machines and established a customer base, you can expand your capacity by adding more Violet printers, or maybe you’re even ready to invest in larger, faster machines like Jasmine or Magnolia to add to your capabilities.

Stepping into digital printing is easier than ever with Violet. Are you interested in learning more about how Violet could benefit your business?

Check out Violet’s technical specifications here.