In a previous blog, we mentioned that rotary screen printing becomes more economical as the run lengths get longer. This raises an interesting question. Is there a break-even point at which the costs of digital and rotary screen printing cross? And if so, does that mean rotary screen printing is always the better choice for run lengths beyond this break-even point? In this blog, I will explain which factors determine where this break-even point occurs.

Expectation versus reality

As a provider of both print methods, SPGPrints often gets questions about the break-even point. There seems to be an implicit expectation that there is one specific answer to this question, but unfortunately this is not the case. Yes, there is a break-even point between the cost of digital textile printing and rotary screen printing. However, this break-even point differs per print job, as there are a couple of factors that affect it.

Quite often the cost price parameter is used as the decisive factor for whether or not to switch to digital textile printing. This focus on purely the cost price per printed meter might be incomplete because more factors influence the choice between rotary or digital for your specific project. For example, rotary screen printing might be the better choice for your design in terms of run length, but if the design is too complicated or has a very long repeat length, the only option for this design might be to print it digitally.

There are a total of 6 factors to be reckoned with. These are all related to run length and design. In the next chapter, we take a look at these factors with the help of visualization.

The break-even point visualized

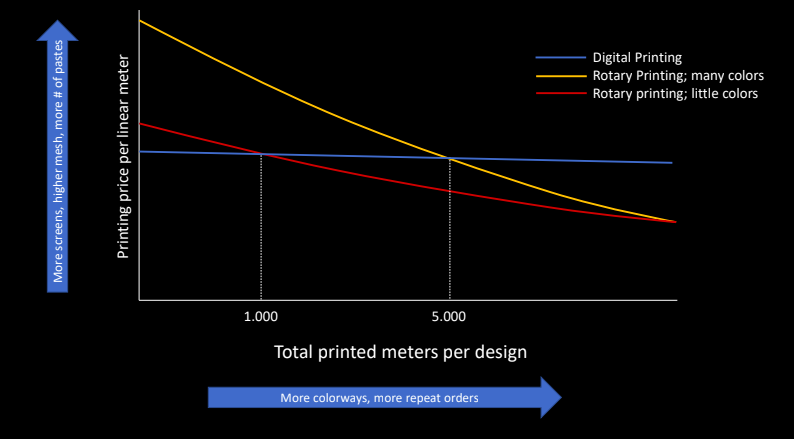

To understand the break-even point, we need to understand what causes the cost difference between rotary and digital. With rotary screen printing, there are the costs of the screens and the engraving of the screens. These start-up costs depend on several factors. The start-up costs are shown on the vertical axis in Figure 1. Digital textile printing does not have specific start-up costs, which results in a straight line if we map this on the horizontal axis: the run length. (Note: both printing methods will probably require initial software work on the digital file; this is assumed more or less equal in both methods).

Conventional printing has higher preparation costs, but lower printing costs than digital printing. As a result, the line of rotary screen printing is a descending line. The break-even point is where both lines cross. This break-even point shifts to longer run lengths when the start-up costs get higher.

Fig 1. The break-even point between digital textile printing and rotary screen printing

Both the horizontal (run length) and vertical (price per meter) axes depend on three factors, explained below.

1.The horizontal axis: run length

The total amount of printed meters you are going to produce of a design determines for a large part the cost of both printing methods. As rotary screen printing is a descending line, it becomes more financially attractive as the printing length increases, so past the break-even point rotary screen printing becomes the most economical option.

1.1 The assignment at hand

Logically, the first factor that determines the run length is the print job itself. What does the customer want exactly? How many meters of the design are needed? And how big is the design itself? The original print job determines the run length and thus a large part of whether or not the break-even point is reached. Therefore, when choosing between rotary screen printing and digital textile printing, the most important question to ask is: “how many meters do I need to print?”

1.2 The number of colorways

The run length of the original query can be increased with different variants of the same design, called ‘colorways’. For example, does the customer need the same design in another color? If you are going to make the same design in more colorways, this lengthens the total run length. This means that with multiple colorways of the same design you can ensure that you will cross the break-even point in the particular job in favor of rotary printing.

Important to realize is that this is possible with the same screens in rotary screen printing. This means that the start-up costs do not go up when deciding on an extra colorway. In digital textile printing each colorway costs the same, so more colorways of the same design can make rotary screen printing cheaper thanks to the long run length.

1.3 Repeat orders

This is quite an intangible parameter, but repeat orders can also determine whether you cross the break-even point. Do you expect to get repeat orders of the same design? If you can estimate this at an early stage, these repeat orders should be added to the calculation of the total print job. In rotary screen printing you can use the same screens again, which means the total run length with these screens will be a lot longer due to the repeat job(s). This is a very important factor to take into account in the initial calculation of the break-even point.

We understand that this cannot always be estimated in advance. If you are not sure whether there will be repeat orders, it is logical to ask whether it is possible to start with digital textile printing and switch to rotary screen printing in a later run. This is possible, but there are some things to take into account before deciding if it is possible in your specific case.

2.The vertical axis: Total cost per meter

On the vertical axis, we see the total cost per meter. At the origin (the run length is 0), this equals the start-up costs. In Figure 1 we have put two different rotary printing cost situations as examples. The red line is a rotary printing job with only a few colors, so it has relatively low start-up expenses and therefore already reaches the break-even point with digital at 1,000 meters. The yellow line represents a rotary printing job with many colors, so it has higher start-up costs and therefore becomes more expensive than digital printing for the first 5,000 meters. Please note that these are examples and the exact break-even run lengths can be different in the case of your company and print jobs.

As you can see, start-up expenses are particularly important in rotary screen printing, as they have a great effect on the final break-even point. But what determines how high these start-up expenses are?

2.1 Amount of colors, screens and printing paste

The first important question regarding start-up expenses for rotary printing is: how many colors are you going to print? The usage of more colors means that you need to buy and engrave more screens so you have more costs.

An often neglected fact of printing with more colors in rotary is that you also need to prepare more printing pastes. The key challenge in that is: how much paste do you prepare for each color? After all, a shortage of printing paste is tricky, as mixing extra paste with exactly the same color at a later stage is difficult. That's why it is very likely that in practice you prepare too much printing paste. This means that you are most probably left with paste that needs to be disposed of in a carefree, chemical responsible manner. This is an unfortunate - but very important - side-effect and means extra costs that have to be taken into account.

2.2 Type of screens: challenging designs

In addition to the number of screens required, the type of screens also plays a major role in your start-up expenses. Very detailed designs require higher mesh screens like the SPGPrints NOVA screens, which are more expensive than lower mesh screens. In short, the difficulty of the design determines how expensive the screens you need are.

2.3 Quality of screens

A rotary screen does not have eternal life. So especially when you are planning to print long run lengths, it is wise to buy a high-quality screen that ensures you can print that whole run with the same screen. You don’t want to run into the situation that when 80% of the print job is done, the screen breaks or becomes unusable for other reasons. Then you have to stop your production because a new screen must be bought and engraved. This means an extra ‘start-up expense’ during the print job.

Rule of thumb for your break-even calculation

To make a trustworthy break-even calculation that allows you to make a good trade-off between rotary screen printing and digital textile printing, you must look at all the factors mentioned above. After all, the turning point where rotary becomes cheaper than digital per meter is related to several factors that all need to be taken into account.

I explained three factors that determine the run length and three factors that determine your start-up expenses. Together, they determine the run length of your print job at which your break-even point occurs. Below that break-even point, digital printing is cheaper. Above that break-even point, rotary printing is cheaper. But as mentioned in the beginning, the break-even point is not a fixed number, as it depends on your company and even your print job.

As a rule of thumb, run lengths below 1,000 meters are in general cheaper to print digitally. Orders over 5,000 meters are almost always less expensive with rotary screen printing. Between 1,000 and 5,000 meters, the factors explained above play an important role in your decision. As discussed, the break-even point differs per print job. Take all factors thoroughly into account in your consideration, when your expected run length is between 1.000 and 5.000 meters, which is quite common in many print jobs today.

Targeted advice for your organization

Are you still not sure whether rotary screen printing or digital textile printing is the most attractive option for your company? Our experts will be happy to provide you with targeted advice, specifically intended for your organization and print jobs. Contact them here.

In our Strategic Guide you can read more about the transition to digital textile printing and what this involves. You can download it here: