Both rotary screen printing and digital textile printing are still widely used in the textile printing industry. Several printing companies, solution providers and trendwatchers expected (or wished?) that digital would one day replace rotary screen printing entirely. The truth is that both types of printing have their own advantages and disadvantages, which makes it logical for them to coexist (as explained in this previous blog). That gives printing companies a difficult choice to make. Which type suits their printing process and products best? Is it more profitable to print conventionally, or does digital printing provide more advantages in the long run? Many printing companies today have both digital and rotary screen printing in house. But when to use which technology?

With the help of the list below, you can make a targeted choice. Not only does this have a positive effect on efficiency, but also on quality and customer satisfaction. That being said, let's take a look at these decisive factors.

1. Run lengths

One of the most important factors determining the choice between rotary screen printing and digital textile printing are the run lengths. Simply put, the amount of meters you have to print determines which of the two printing technologies gives the lowest total cost per meter. With a smaller amount of meters - as a rule of thumb we take under 2,000 meters - digital printing will always be cheaper. Rotary screen printing has a set up costs (f.i. because the design has to be separated into colors and screens have to be engraved first), where digital has little or no set up costs. However, these set up costs are negligible if they are distributed over many printed meters, so generally above 5,000 metres rotary screen printing is the cheaper choice. In between these run lengths, there are other factors like the number of colors and number of colorways per design that determine where exactly the break-even point in cost price lies.

In this blog we explain this break-even point in more detail.

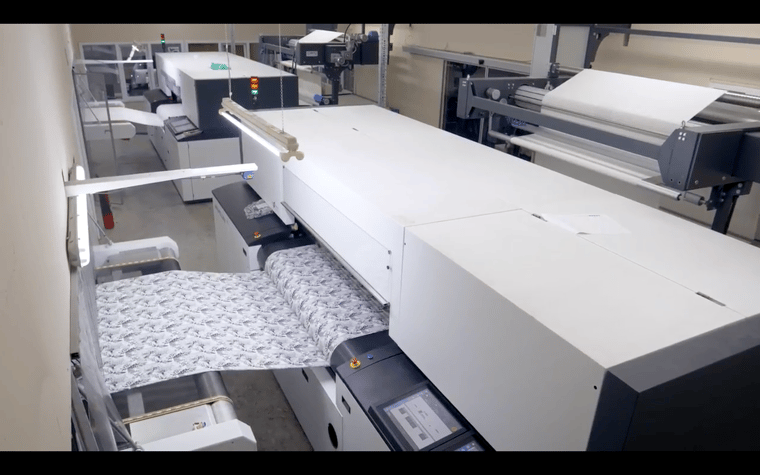

Logically, the cost price per printed meter is often decisive in the choice you make as a company, and rotary screen printing is generally always cheaper when printing larger run lengths. We have to make a nuance here: nowadays, digital single pass machines are so fast that they can also print longer runs in an acceptable time very well, and the cost per meter is lower than many printing houses expect from digital.

2. Lead time

The second point also has to do with the production process, just like the amount of printed meters. The requested delivery time from the customer can have a major impact on the choice between rotary screen printing or digital textile printing.

Companies that print for large brands often are forced to short and strict deadlines. The brands simply deliver a USB with the designs and need it in large quantities within a few days. That is hardly possible with rotary screen printing. I already mentioned that rotary screen printing needs a set up time due to the engraving of the screens, but there is more. Often color separations have to be made and furthermore it takes longer to start up the rotary machines than their digital equivalents. Adjusting the registering of the separate colors in a rotary printing machine takes time (and meters of fabric!). In short, the total lead time of rotary screen printing from receipt of designs until delivery of printed meters generally is longer.

If the requested delivery time allows for it and your design can be reduced to less colors (one per screen), then rotary screen printing is the logical choice for larger print runs. If the end product has to be there within a very short lead time, digital textile printing will be the faster choice. In that case the printing company can ask for a premium pricing (fast track delivery) and give the brand a choice: fast delivery or cheaper price.

3. Complicated designs

Not only production factors like the run lengths and lead time determine your choice. Of course, the design at hand plays a major role in the decision between rotary screen printing and digital textile printing as well.

Reason for this is that not all designs can be printed with just any type of printing. Complicated designs with many different colors (or even photographs in the print), or designs that have long repeats cannot be printed with rotary. So only flatbed screen printing or digital remain as possibilities. Flatbed screen printing does not have a lot of the cost advantages that rotary has over digital, so the chance that digital as a solution wins over flatbed screen printing is quite high.

4. Jewelry colors and burn-out printing

The same is true the other way around: there are also design limitations to digital textile printing. For example, true shiny gold color and other so-called "jewelry colors" can only be made with rotary screen printing. Digital textile printing can only photo-simulate these colors but they will never be shiny as true jewelry.

The same applies to burn-out printing, a special printing technique in which a screen prints a design with a special chemistry on the fabric. A post-processing burns the parts of the fabric away resulting in semi translucent fabric. This special chemistry cannot be jetted through an inkjet head as it would permanently damage the heads. A nickel screen is resistant to these chemicals. Again, if these are the kind of designs your company needs to print, your choice is simple. For jewelry colors and burn-out printing, digital textile printing is not an option.

.jpg?width=860&name=Digital%20Gold%201%20(1).jpg)

5. Light colors, dark backgrounds

Another factor in the type of design that will instantly determine your choice is when you have to print light colors on a dark background. Almost all commercially available digital textile printers use water based non-opaque inks so the lightest color they can print is the color of the fabric. There are some pigment printers that can print on black fabric by first laying down a layer of opaque white ink, but the cost per m2 of such print makes it prohibitive for large prints and/or long runs. Generally those prints also never reach the brilliancy of for instance reactive printing.

A final challenge for digital textile printing is the printing of blotches, large areas of one color. Uniformity is key there, and as digital printers build up the image by lines that come in time, every small disturbance of such lines becomes visible and destroys the uniformity. In rotary printing this is not an issue, provided the screen is engraved uniform.

6. Client's wishes and demands

In point 1 to 5, we covered the production factors and design factors of your printing process. However, printing orders are not as black and white as some of these points make it seem. Some designs might better match rotary screen printing and a shorter run length might push you towards digital textile printing, but what if the client has specific wishes?

If the client or customer is specifically interested in digital textile printing, but is used to the prices of rotary screen printing, a discussion might be ignited. Hopefully, the previous points help you to explain to the customer why one is much more expensive than the other and why the other might be the better option.

That being said, the customer is king. As a printing company, it is your job and responsibility to give the best advice possible, but if the client demands a certain type of printing, there is always a possibility to comply. Be aware that there might be certain limitations (resolutions, lead time, etc.) and make the client familiar with these limitations. You will have taken your responsibility, but the choice ultimately depends on the customer's demand.

7. Repeat orders

The last determining factor also has to do with specific order wishes. Imagine the following situation: you print 3,000 meters digitally, and the end product is a huge success for your customer. Now, there is demand for a new print run, this time of 10,000 meters in total. In point 1, you could already read that printing more than 5,000 meters is generally always cheaper with rotary screen printing.

The cheapest and most efficient way is to make the new print run with rotary screen printing. However, the first run was digitally printed and of course you want the next run to be almost identical to the original product. What to do now?

Luckily, there are ways to make sure the match between rotary screen printing and digital textile printing is as good as possible. This brings us back to the original question of combining both types of printing. Can you make a transition between repeat orders if you have both types of printing in your production process?

In an upcoming blog, we will explain in further detail how you can make this transition between rotary screen printing and digital textile printing. For the time being, our specialists can help you to make this transition smoothly. Contact them here with any questions about both types of printing.

3 categories, 1 conclusion

The above-mentioned 7 determining factors to help you with your choice between digital textile printing and rotary screen printing, can be divided into 3 categories:

- Production parameters (1 & 2)

- Design limitations (3, 4 & 5)

- Order specifications (6 & 7)

In short, whether your company and customers are best aided with a digital textile printer or a rotary screen printer, depends on your production process, the designs you must be able to make and the wishes of your customers. Sounds straight-forward, right? If you are still having trouble with these differences and want some extra advice, feel free to contact us with any questions.

If you plan on switching to digital printing or combining digital machines with your conventional printers, our Strategic Guide to Digital Textile Printing can get you started. This free guide can be downloaded here: