The more sustainable aspect is mainly in the fact that steaming and washing is no longer necessary. This is because a sublimation printer first prints on transfer paper, which is then transferred to textiles. This paper for sublimation printing is an essential factor.

This blog will discuss the paper used for sublimation printing and how this process is optimized for the best possible printing result.

The process of sublimation: textile without washing and steaming

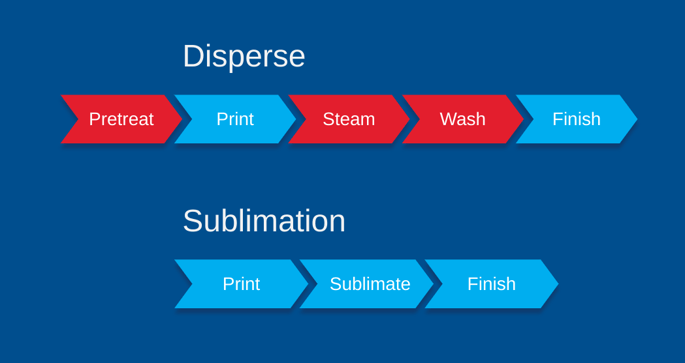

The print workflow works slightly differently in sublimation textile printing than disperse textile printing. In sublimation printing, the design is first printed on transfer paper. When this paper is pressed onto the substrate, the heat causes the sublimation ink to become gaseous. The ink detaches from the paper and penetrates the fabric.

Paper for sublimation printing: coated vs uncoated

For this process, sublimation paper is a crucial factor. Over the years, transfer paper for sublimation printing has become lighter and lighter. In the past, a heavier paper was used, always requiring a coating. Back then, 100 g/m² paper was very common. The development of technology means that thinner, lighter paper can be used nowadays. SPGPrints’ new textile sublimation printer Rose can even handle sublimation paper of 31 g/m².

For optimal results, coated paper is still the best choice. Uncoated sublimation transfer paper is also widely used, as it is lighter and cheaper. However, depending on the paper used, the print quality of the fabric can vary. When using uncoated paper, the ink flows more into the paper, causing a lower degree of ink transferred onto the polyester fabric. This results in less beautiful colours or unsharp images.

Maximize efficiency: shipping sublimation paper instead of fabrics

One tactic often employed for optimal efficiency is to separate the printing and calender ring processes. This is what many sports brands operating around the world are opting for nowadays. They first print the design on sublimation transfer paper and then ship it to their facilities worldwide. There, finishing is done at the time the products are needed.This has a couple of advantages:

- Shipping paper is much cheaper than shipping fabrics.

- These companies exploit the speed of their sublimation printing machine better.

- It is easier to ensure colour consistency by making sure that all items are printed on one machine.

- Waste is minimized. Unused printed paper has less environmental impact than unused stock of clothing.

This provides particular benefits when using the Rose (the latest digital sublimation printing machine from SPGPrints). This new sublimation printing machine can print as much as 400 m² per hour. Calenders are not that fast. Knowing that calendering at 200 degrees takes half a minute per meter, a quick calculation tells us that it takes four calendering machines to keep up with one Rose.

If the sublimation process and finishing occur in the same location, this slows down the process. Having the sublimation printing machine print the sublimation paper first and finish the products wherever they are needed results in a more efficient process. Another way to prevent slowing down the printing process is to add more calenders.

Interaction between sublimation paper, ink and sublimation printing machine

Earlier in this blog, we mentioned that sublimation paper must be able to carry the right amount of ink suitable for a specific polyester fabric and textile application. We also mentioned that light transfer papers are getting more popular over the years. This is strongly related. How much ink the paper can carry partly determines what textile application it can be used for. Paper that cannot fully carry the desired amount of ink results in design limitations. In the past, only heavier, coated sublimation paper could adequately absorb the ink.

The above process is an interaction between printer, ink and paper. The role of the sublimation printer is an important one. If the paper in the printer bulges too much (and thus touches the nozzles) at a certain amount of ink, errors or even damage will occur.

To ensure maximum runnability, the experts at SPGPrints conducted extensive testing on the Rose sublimation printer. They found that Leaf sublimation transfer paper handles the same amount of ink as lighter-weight paper. 60 g/m² sublimation paper was found to have similar capabilities compared to 90 g/m² gram sublimation paper of other vendors.

Although the sublimation printer and the transfer paper are directly connected to each other, the formulation of the ink itself is also fundamental. Here, one should always aim for inks with as much dye as possible without loss of runnability.

Your own future-proof printing process from one supplier

When all three main factors - sublimation printer, ink and transfer paper - come from one supplier, you know the interplay is well-tested and optimized. That's why SPGPrints offers all these components under one roof, including application support.

The result is maximal runnability within your sublimation printing process. You can read more about improving runnability in this blog.

Curious about what a sublimation printer can do for your printing process? Request a Personal Sample for your application and make your printing process future-proof:

You can also watch our webinar about digital sublimation printing here. If you have any other questions about setting up a future-proof, sustainable printing process, feel free to contact our experts; they’d love to help!