The outbreak of COVID-19 was a drastic event that changed the world harshly. In this previous blog, I already explained what the first consequences were and what I expected to be the long term impact for textile printing. Now that the world is slowly getting back to a more normal situation, we can start analyzing: what consequences has COVID-19 actually had so far on our industry? How do you deal with machines that have not operated for a long time? Can I still use the inks that I have in stock? And what can we expect in the upcoming months?

In this blog, I will explain more about starting up again after COVID-19 by responding to some frequently asked questions about inks, machines and getting back to printing.

Do you need to shake ink after a long downtime?

One of the questions we’ve received during the start-up after the crisis had to do with the state of the inks. After all, the machines have been at a standstill for months and the ink hasn’t been used since. Can the inks be used again instantly, or should the ink be shaken first, in order to avoid clogging in the heads?

The answer to this question is simple: do not shake your SPGPrints inks. In fact, thorough shaking could cause more damage than it does well for the inks. Therefore, we strongly discourage shaking inks when restarting your printing process after COVID-19.

We realize that this question comes from the common experience with normal inks or paints, that often do need shaking and/or stirring after a longer standstill. However, reactive and acid inks are not like paints: the color molecules are completely dissolved in the liquid (like sugar in your tea), so they cannot create sedimentation. For sublimation and disperse inks, which have color particles floating in the liquid, one could expect the necessity to stir or shake. But the digital sublimation and disperse inks of SPGPrints are designed to keep the dyes in dispersion and not to create sedimentation, even when they are not used for a long time. In other words: a long downtime has no effect whatsoever on SPGPrints digital textile printing inks.

While downtime should not harm the inks, inks may suffer from environmental storage conditions. Therefore, make sure that the storage has a normal environmental conditions and that inks have not undergone any significant temperature fluctuations during the corona outbreak. If the temperatures in the printer room and the warehouse stayed within the normal values, starting up with the same inks will not be a problem.

Re-using ink that was already in the ink circuit

The above-mentioned guidelines apply to inks that are still in their original cans. If the ink was already in the ink circuit before production came to a standstill, we recommended at that time to our customers to keep the printers switched on and to run them for a short time each day. If the customer insisted on switching off the printer, then we advised to remove the inks from the printer and fill the ink channels with cleaning liquid. Otherwise, the inks may dry within the printer and cause clogged heads, for instance if the capping station is not 100% air closed.

The Best Before Date: shelf life after COVID-19

SPGPrints Ink cans are provided with a “Best Before Date (BBD) on the label of each can. The BBD is added at the moment the ink is produced, and typically covers a period of two years (depending on the ink chemistry). For recently introduced ink types, we usually start with a BBD of just one year, because we want to be absolutely sure of our guaranteed lifespan. The BBD does not mean that the ink is unusable after this date, but before this date we can guarantee optimal quality, based on laboratory tests that simulate this life span.

Due to COVID-19, a lot of unused inks were stored and the BBD might be getting closer. To anticipate on questions about this BBD, SPGPrints used the corona lockdown time to test all types of inks again on their shelf life, obviously starting with the ones that have the shortest life expectancy today. In a lot of cases we were able to give those ink types a new, prolonged BBD. Our customer service can advise on each ink type whether we can guarantee a longer useable timeframe than their pre-estimated BBD. When in doubt, we can even check the batch number of the ink that reaches its BBD and our R&D specialists can use the sample of each produced batch, that we store locally for reference, to determine if that specific batch can still be used.

If the BBD hasn't expired yet, you can use the ink without any doubt when restarting. Having said that, of course you can always consult our customer service if you have any doubts or other questions about ink usage.

Our JAVELIN & PIKE machines

All of our customers received instructions about how to turn off their PIKE and/or JAVELIN machines for a longer period of time and how to start them up again, if this is their preference. However, one of the nice features of our digital printers JAVELIN and PIKE is that they have a system of continuous recirculation of inks. This Unique Selling Point was originally designed to avoid the need for a purge or a thorough cleaning to wake the printer up after standing idle for while. Competition printers often need such a ‘wake up’ already after being idle for a few hours. PIKE and JAVELIN can instantly start printing. Now this feature turns out to be helpful even during longer standstills. As long as the SPGPrints printer remains switched on, no problems can occur. So we saw our customers opt for this scenario: besides the consumption of a small amount of electricity there was no hassle of shutting down the machines, throwing away inks etcetera.

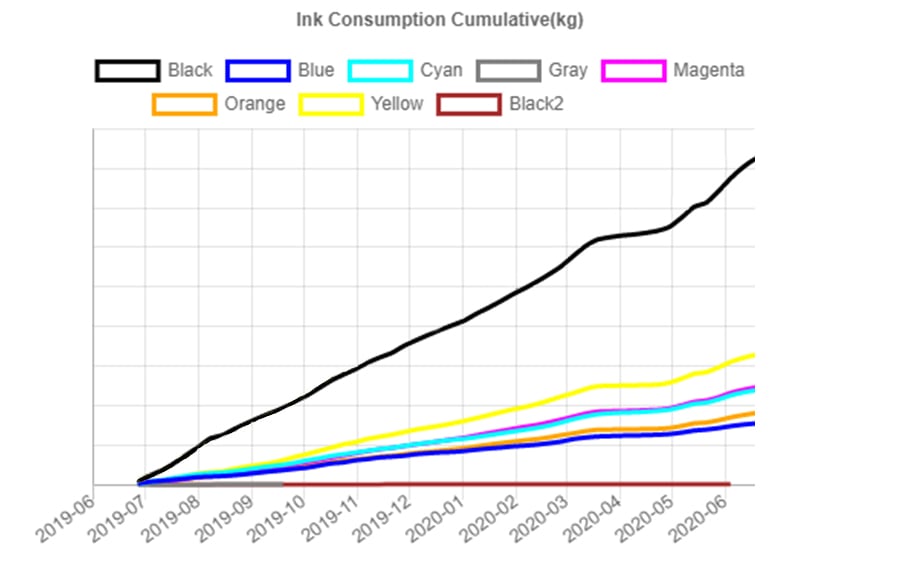

Fig 1. Ink consumption per color on all PIKE and JAVELIN printers measured over the last 12 months.

The corona effect in April and May is clearly visible.

Starting up other printing machines with our inks

If you use a third party printer in combination with SPGPrints’ inks, and you switched off the printer during the lockdown, we can also assist you in getting it up and running again. Depending on whether you emptied the ink channels when you shutted down, or left the inks in, this can be more or less work. In any case, unless you are very experienced with cleaning and purging heads, you should ask for help from the machine manufacturer or from us to help you restart again.

When does digital textile printing get back to its old level?

By now, we can see that several of our previous speculations on the effects of COVID-19 on the printing industry, are now starting to become reality. Slowly the world of (digital) printing is waking up again. However, the big brands are still cautious about placing orders. They first want to make sure that consumers' buying behavior gets back on track, and the shops gradually sell the summer collections that got in stores last March.

In the meantime, designers have continued their work and the demand for rapid printing has increased. Therefore, the expectation is that digital textile printing is going to benefit more than the conventional market. Whether we reach the old level again at the end of the year, is still unclear. Opinions differ on this matter.

One of the most important factors is what the economic recession is going to do for the purchasing power of customers. Whatever the future entails, SPGPrints is ready to help our clients to get back on track. Together we make sure that both digital and conventional printing wake up properly after COVID-19 and are ready for what the future brings.

On site specialists

SPGPrints has offices with sufficient ink supplies and specialists all over the world. As one country’s reboot happens quicker than another, we are able to redistribute inks to provide each country with enough ink. Another benefit of having specialists on stand-by around the world, is that each region has local specialists that can come by and give you advice on site. This way, we can provide the most efficient assistance for companies to get back on track.

In short, we can check the expected lifespan of your inks, clean heads from our own printers as well as those of other printers and offer local support all over the world. Curious about what SPGPrints can do to help your company wake up after COVID-19? Get in touch with our specialists and ask for their advice here:

.jpg?width=760&name=PHOTO-2020-03-06-08-15-08%20(2).jpg)