Nowadays, many printing companies combine both digital textile printing and rotary screen printing. An understandable choice, because both print forms have their own advantages and disadvantages. By combining them, you get the best of both worlds.

However, using two printing processes side by side also raises questions. One of the frequently asked questions to SPGPrints from our customers has to do with textile sampling. Can you make a digital sample for a design that will be printed conventionally? And if you can, does it make any sense at all to do this?

The importance of textile sampling

Let's start by emphasizing the importance of textile sampling. Why is it necessary to make a sample before printing the entire batch?

In any printing industry it is actually necessary to sample. After all, you want to make a test print first to see if the result looks good. In the graphics world this is called a proof. A small example of this is a birth announcement card: if the first proof looks good and is approved by you (the client), then the printer produces the production batch to let everyone know that a new family member has been born. If, for example, the name is misspelled in that proof, you can still fix it before you release it to the printing company.

The importance of this really becomes clear when there is an error in the final print run. If the same error occurs in the proof, the client is responsible. After all, they should have seen it during the proof run. If the proof was correct but an error has emerged in the final print, the printing company can be held responsible. This proof is therefore often referred to as ‘contract proof’.

This responsibility issue is also true for the textile industry, where they use the term ‘sample’ for a proof print. For example, a brand owner has a sample made by a producer and this sample will be reviewed by their development team. The final print run that they commission to a textile printing company will be compared with the sample. If this looks the same, the producer has fulfilled the assignment. If the print run contains an error but the error is also in the sample, the brand owner as the client cannot hold the producer liable. They should have detected the design error themselves in the sample and take measures to correct it.

Conventional textile sampling: time is of the essence

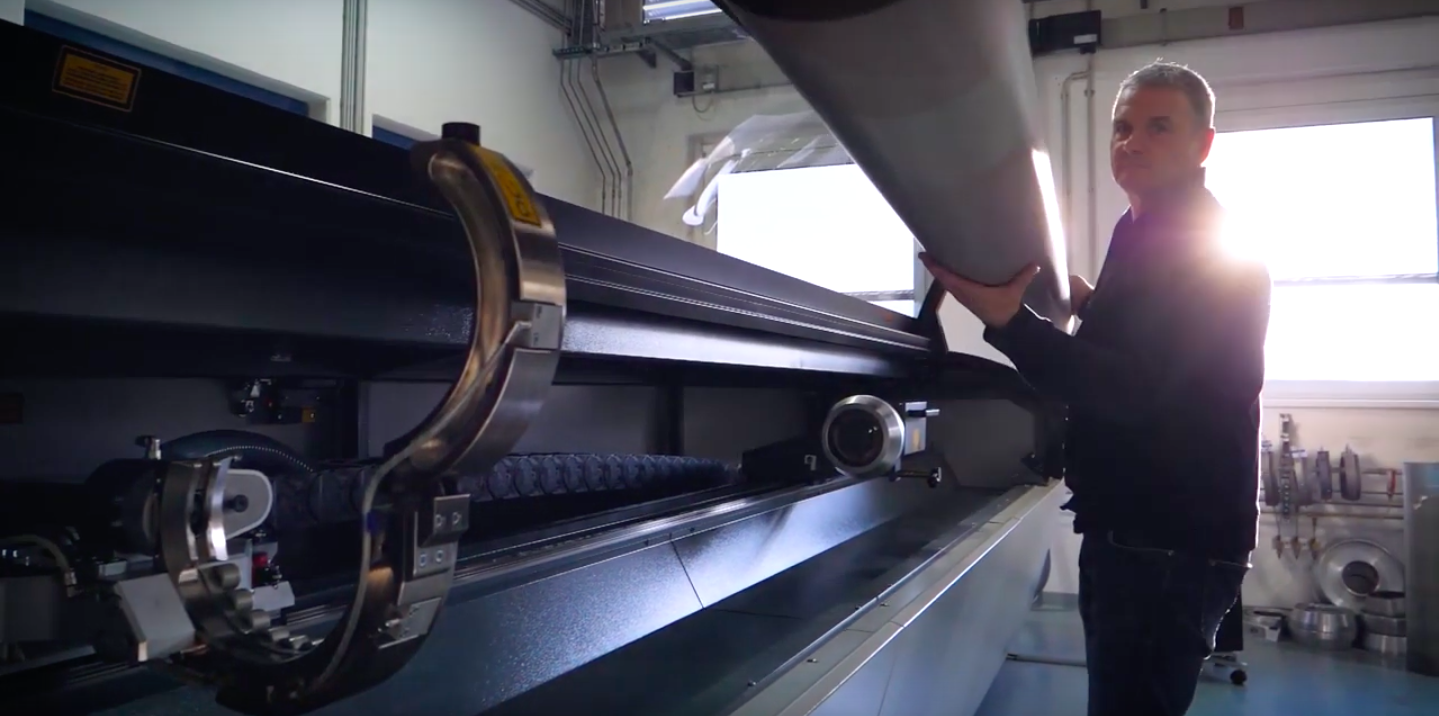

Samples have been made long before the invention of digital textile printing, but the conventional making of samples takes a lot of time. That’s because samples are preferably printed directly on a piece of fabric, and not on paper. After all, this gives you the best comparison with what the final printing result looks like. The disadvantage for rotary screen printing is that screens have to be made in order to be able to print on textile. These are often flat screens that are used on a sampling table. This limits the possibilities to change the design: for each change and corresponding test round, new flat screens have to be produced.

The advantages of digital textile sampling

In contrast to conventional printing, digital textile printing gives you the possibility to directly print a sample on textile. Apart from making the (flat) screens, the overall preparation time is also longer. So with digital textile sampling you actually have a piece of textile in your hand much quicker.

For fashion collections, samples are suitable for direct use to make catalogs. As you have no limitations in the amount of samples you produce digitally, it is easy to create a series of designs that are not yet in production. This enables you to test-market all the designs that you create, and only when the orders come in thanks to the catalog, the designs are produced at a larger scale. This is often referred to as ‘digital printing helps you to change from trying to sell what you already produced to produce what you already sold’.

Digital textile sampling for rotary production: does it work?

Because of the above mentioned advantages it seems a good idea to print digital samples, even if the final design is printed with rotary screen printing. However, there is one major aspect to keep in mind here.

Digital can print much better quality than rotary screen printing can match. Therefore, the resolution of digital samples is much higher than the conventional printers can reproduce. If the sample is of much better quality than the final print, you can get the customer on the wrong track. On the other side — the side of the printing company — it is impossible for the printer to reproduce the sample, which causes discussions about the quality and the final production run. Here the previously mentioned responsibility issue (sample comparison to production run) applies.

In the 1990s, when digital printing first emerged, the BestImage software package was developed by SPGPrints for this purpose. This uses a so-called raster simulation, which can simulate a conventional printing raster into the digital file. This allows you to create the “perfect” sample: a digital sample that perfectly predicts what conventional rotary printing will look like.

The sampling dilemma

Before you start printing a new design, you have to decide how you're going to produce it in the end. Based on that you have to decide how you're going to make your sample. Companies that have both rotary screen printing and digital textile printing in house have three possibilities when it comes to samples:

- The old-fashioned way: you make a sample with flat screens on a textile sampling table and then print the production run with rotary screen printing.

- Hybrid textile sampling: you print a digital sample, but the production is done with rotary screen printing. This provides a difference in print quality of the sample and the rotary screen production, unless you use the BestImage software from SPGPrints.

- Fully digital: You use both digital textile sampling and digital textile printing.

In an earlier blog we wrote about the choice between digital and rotary screen printing, a consideration that is especially important when it comes to textile sampling and run lengths.

Managing expectations

No matter how you turn it around, managing the client's expectations is the most important thing when it comes to textile sampling. Especially if you choose to sample digitally for rotary screen printing, it is important that you manage the expectations. The result of rotary screen printing will never be as detailed as the digital sample. The same applies if you make a digital sample and the customer is so satisfied in the end that he requests a big run. Manage the expectations and outline the options: a large run is cheaper with rotary screen printing, but that does mean that the quality will never be as good as the sample was. Digital textile sampling and digital printing is becoming more and more common, but digital printing is (especially when it comes to longer runs) much more expensive than rotary screen printing.

There are quite a few differences between the two types of printing. Still you can use digital textile sampling — which is a lot faster than conventional textile sampling — for rotary screen printing. However, you need to manage your customers' expectations well. This way you can avoid problems and get the most out of both print forms.

More strategic advantages

Are you not yet using digital textile printing or digital textile sampling and would you like to discover what this can do for your company?

In our Strategic Guide for Digital Textile Printing we tell you all about the strategic advantages of digital textile printing and how you can get the most out of it. You can download the free guide here: