To resolve common misconceptions about these dyes for once and for all, this blog compares both dyes in this blog in terms of composition, deepness of black, sensitivity to processes and costs. We will refer to them as MCT and VS. To start with our comparison, let’s look at what MCT and VS are and what the main difference between both reactive dyes is.

The chemical difference between MCT and VS

Reactive dyeing is the most common method in coloring cellulose fibers, like cotton or viscose. This makes the usage of reactive dyes very common in the digital textile printing industry. In the past, when dyes were first made, only vinyl sulfone was being used. Nowadays, the conventional side of printing has shifted mostly to MCT dyes, as they are less sensitive to variations in the process and show more vivid colors than the VS dyes.

Before explaining why VS dyes were initially preferred for Black in digital textile printing, but companies now increasingly ask for MCT Deep Black, let’s look at what MCT dyes and VS dyes are and what differentiates them. To understand the difference between VS and MCT, you need to understand the fixation process of these reactive dyes. Reactive dyes are called reactive because they contain a chromophore that chemically reacts to the specific groups of the fiber, creating a true covalent bond. Due to this covalent bond between fiber and dye molecule the reactive dyes can achieve excellent fastnesses.

The reactive group that is attached to the chromophore is what differentiates MCT dyes and VS dyes chemically. The chromophore is determining the color. In MCT dyes, the adhesion to the cellulose is established by the reactive monochlorotriazine group, while in in VS dyes the reactive group is vinyl sulfone.

Mixture of colors versus pure black

VS dyes owe their intensity to the chemical composition of the colors. This is especially noticeable in the color black. Black VS dyes consist of a mix of maximum 2 dyes (majority navy blue with some orange), whereas a black MCT dye is by definition a mixture of multiple colors that create the color black together. Some ink suppliers claim their black MCT dye is “pure black”, but by calling it pure, they imply that it consists of a black molecule. That is not possible with MCT dyes. What they often mean is that their MCT black is very neutral. Other MCT blacks tend to be more reddish (by preference of region or printer; see our blog about comparing colors in textile printing ink.

The fact that black MCT is a mixture of multiple colors and black VS has one dominant color and a supportive color, it results that a black VS dye is always purer and therefore perceived deeper than its MCT counterpart. On the other hand, MCT dyes provide printers with more flexibility in the printing process due to the fact that their finishing process is less critical.

Being a mixture of multiple different colors has another consequence for MCT dyes. Colors are indicated by a CI-number (their Color Index). Not all CI-numbers are suitable for digital textile printing. Some CI-numbers can’t be applied used because of the size of the color molecules. Therefore, not every MCT mixture for conventional textile printing can also be used in digital textile printing.

The L-axis of MCT and VS

Especially the deepness of black is an important factor in fashion and thus an important decision factor when selecting reactive dyes for digital textile printing. LAB is an accurate way of measuring colors with three values: L, A and B. The color value “L” - stands for “Lightness” - is a very important measurement for the color black.

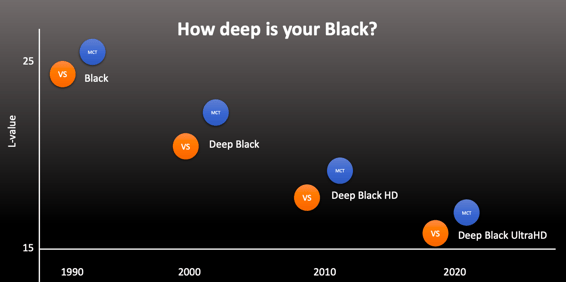

On the L-axis, 0 is black and 100 is white. Printing a L-value of 0 is still impossible in textile printing, but over time the industry managed to create deeper and deeper blacks. The table below shows the different black depths of our different MCT and VS dyes.

As you can see, for every black MCT dye there is a VS alternative which provides even deeper black printed color.

Steaming processes

The way a reactive dye fixates causes other differences between MCT dyes and VS dyes. For example, VS dyes are more susceptible to minor changes in the steaming process. If you steam the same printed fabric on three different units of the same steamer model, it may look different on the fabric steamed on one steamer in comparison to the other two fabrics printed on the other steamers. For example, one might look more brownish or even pinkish or another result is more bright than the others. Because of this challenge, demand for MCT dyes is increasing, as MCT dyes are les sensitive. However, the intensity of VS dyes is higher.

This critical steaming sensibility of VS dyes is caused by the way of steaming. In the early days, back when VAT dyes were used as a standard, all steamers had to be completely airtight. Oxygen was damaging to the process, which is why steamers had to be airtight or sealed.

MCT dyes can be used in this standard process without any difficulties. However, if you want to use VS dyes, it is essential that some oxygen gets in during the steaming process. This is due to the fact that VS dyes are sensitive to hydrolysis which can happen if no air is let into the steamer.

This would mean, that when you would want to use VS dyes because of their intensity, you would have to open up your steamer. Luckily, most dyes do not contain any VAT colorants anymore, which means it is no problem to “unseal” steamers without risking the quality of other dyes used.

For experienced textile printers, it is ususally no problem to handle the more sensitive VS dyes. However, for new printing companies with less experience, it can be difficult to master the black VS dyes in the process. Also for companies that utilize multiple steamers or even locations to produce their quantities, it is desirable to rule out the sensitivity to any possible process fluctuation.

A steamer that is optimized for digital textile printing is able to let in air during steaming. The newest steamers are able to automatically suck in the required air for the steaming process. Better isolation and more sustainability are often selling points of new (digital) steamers. Old steamers can also be adjusted in order to let in air, but convincing a printing company to open up a steamer that they were told to keep closed for 30 years can be a hard job.

The financial aspect: what do reactive dyes for digital textile printing cost?

The dilemma between MCT dyes and VS dyes is also noticeable in pricing. Generally, MCT black ink is more expensive than a VS black ink.

The individual ingredients for VS inks are cheaper. At the same time, VS is providing a deeper black. This is why making the exact same tone with MCT inks is more expensive. Furthermore, the purifying process is also a factor that increases the price. Purifying VS dyes is less time consuming than MCT dyes. In return, MCT is more stable and less susceptible to changes in the printing process.

Pros and cons: conclusion

Now that we've talked about composition, sensitivity, color intensity and price of reactive dyes in digital textile printing, we can strike a balance between MCT and VS dyes.

In short, VS dyes are more attractive in terms of pricing and color density, but you need to know exactly what you’re doing and you have to be in full control of your production process. In terms of sensitivity, MCT is the safer choice, but to create an equal quality, MCT is more expensive.

If you have any more questions or if you would like more information about the different types of dyes, please feel free to contact us. Our specialists are happy to inform you about the technical background of reactive dyes. We can help you choose the right reactive ink for your printing process.

As you could read, one of the things that differs between conventional and digital textile printing is the steaming process. Do you want to make the transition to digital textile printing? We recommend reading our Guide, which covers all the factors relevant to this switch: