Over 140 apparel companies have already joined the Science Based Target Initiative, a commitment to cut emissions across the industry. It’s a positive start, but we believe that every business must attempt to minimize its carbon footprint and improve ESG performance – and new technologies can help.

Here are six things every printing business should consider doing to reduce its carbon footprint:

#1 Calculate your environmental footprint with a lifecycle assessment

To cut carbon emissions, you must first measure them. A lifecycle assessment systematically records every process and activity to calculate a product's potential environmental impact.

It’s essential that you consider the entire lifecycle, including recycling and re-use. At SPGPrints, we call this a cradle-to-cradle lifecycle assessment. There are several tools to help you, including Ecopoints and Higg Index. Both systems take information about the products, processes, and procedures used during production. They calculate your environmental impact from raw material handling to finished material and transportation.

Lifecycle assessments provide critical insights into your process. As a result, it's easier to identify the steps in your production process with the highest potential to innovate to reduce emissions.

#2 Tackle transportation costs

Transportation is responsible for a considerable amount of carbon emissions in the global textiles industry. To illustrate: To deliver bed linen for one hotel bed for one year, transportation accounts for 8kg of CO2 emissions per year. Critically evaluating your purchasing policy can make a big difference. You significantly reduce your environmental footprint by buying locally sourced materials and producing closer to your customers' markets.

Also, consider expiry dates in decision-making. By buying and printing batches you will sell, you can prevent waste. As well as saving money, you’ll cut carbon emissions from the transportation and processing of waste.

#3 Update printing processes

Many companies are considering the benefits of digital printing as a more sustainable alternative. Digital printing is a precision process that uses less ink and leads to less waste in itself as the ink droplets are being printed very precisely onto the fabric. In addition, orders are easy to process, with printers able to start production almost immediately after receiving an order – cutting inventory and faster turnaround times.

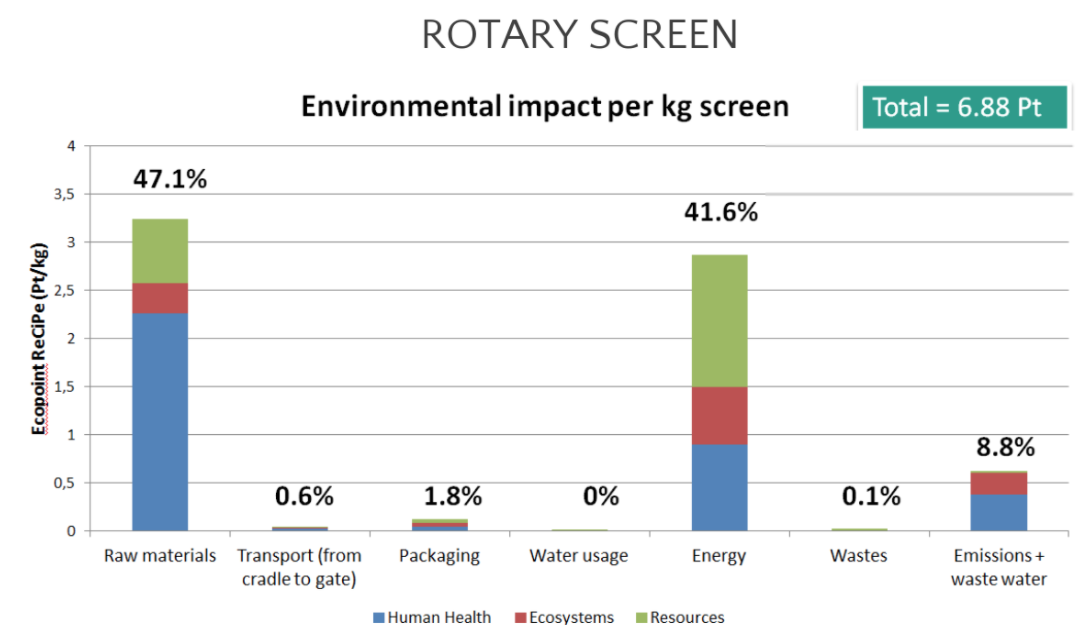

The environmental impact per kg screen for rotary screen printing

The environmental impact per kg screen for rotary screen printing

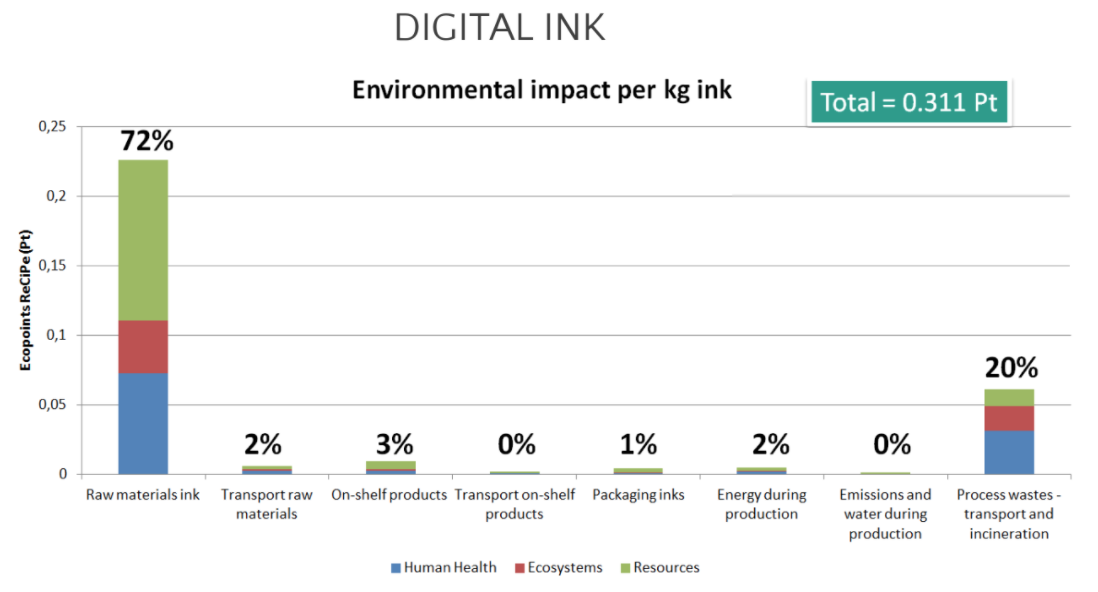

The environmental impact per kg ink for digital textile printing

The environmental impact per kg ink for digital textile printing

Not considered digital printing before? A new generation of high-quality, affordable digital printers is redefining expectations and making digital a realistic option for printing businesses of all sizes.

SPGPrints has recently launched a new, affordable digital textile printer: Violet. Curious to see it for yourself? We have proudly shown Violet as one of our ‘Crown Jewels’ on our stand at ITMA 2023 in Milan. Acces the Violet brochure below:

#4 Print what sells, not what's printed

Fast fashion is an excellent illustration of how consumer demand is changing the industry. Fast fashion enormously pressures the environment through water use, pollution, waste and carbon emissions. Instead of printing what sells, don't sell what's printed. Therefore, fashion brands should put more effort into precisely estimating the meters of fabric they will sell - and base their printing job on this estimate. They should even consider selling the remaining stock in a new season or year. This will prevent waste as much as possible.

Digital textile printing (and conventional textile printing too) enables fashion brands to print small batches and place repeat orders when a specific textile or garment is selling well. This can dramatically reduce waste and reduce inventory, as well as being more reactive to customer demands. This gives you more flexibility in both conventional and digital printing. For conventional printing, however, be mindful to take longer turnaround times into consideration.

#5 Consciously manage your water usage

Water usage and waste are massive in the textile industry, so reducing them must be a priority. In one example, a SPGPrints customer found that switching from rotary printing to digital printing reduced the amount of water used by an incredible 70%. That doesn’t mean that rotary printing cannot be more sustainable as well. On the contrary: the high water consumption in rotary offers great opportunities for water savings.

It's not the only way to cut waste and emissions. For example, switching to pigment-based paste or inks drastically reduces your water usage by removing the need for washing and steaming.

Of course, you’ll still need to use water in your processes, but consider how you can more effectively handle and purify your wastewater. At SPGPrints, for example, we apply wastewater treatment in our production process. This process removes contaminants from wastewater to be safely returned to the water cycle.

#6 Partner with a reliable supplier

Textile printing businesses serious about change should seek suppliers who share their commitment to sustainability and environmental values. Your suppliers should be committed to working with you to cut carbon emissions and provide insights and advice on the following:

- How to reduce your ecological footprint in general

- Recent innovations that contribute to improved waste, water, and energy management across your entire printing process.

- The most optimal deployment of your people, machinery, and capital

When selecting partners, don’t be afraid to be critical and push them for answers to essential questions, such as:

- Are your fabrics sourced and crafted responsibly?

- Do they hold sustainability labels, like ECO PASSPORT by OEKO-TEX® or GOTS?

Printing Tomorrow

SPGPrints aims to be a reliable sustainability partner for our customers. “Printing Tomorrow” is about more than shaping the future of printing technology; it's about doing everything possible to ensure a sustainable future for our planet.

We’re focused on developing more sustainable products and solutions. Our experts are developing new processes for greater production efficiency. We’re committed to building high-quality machinery, with our local service network ensuring the longest productive lifespan.